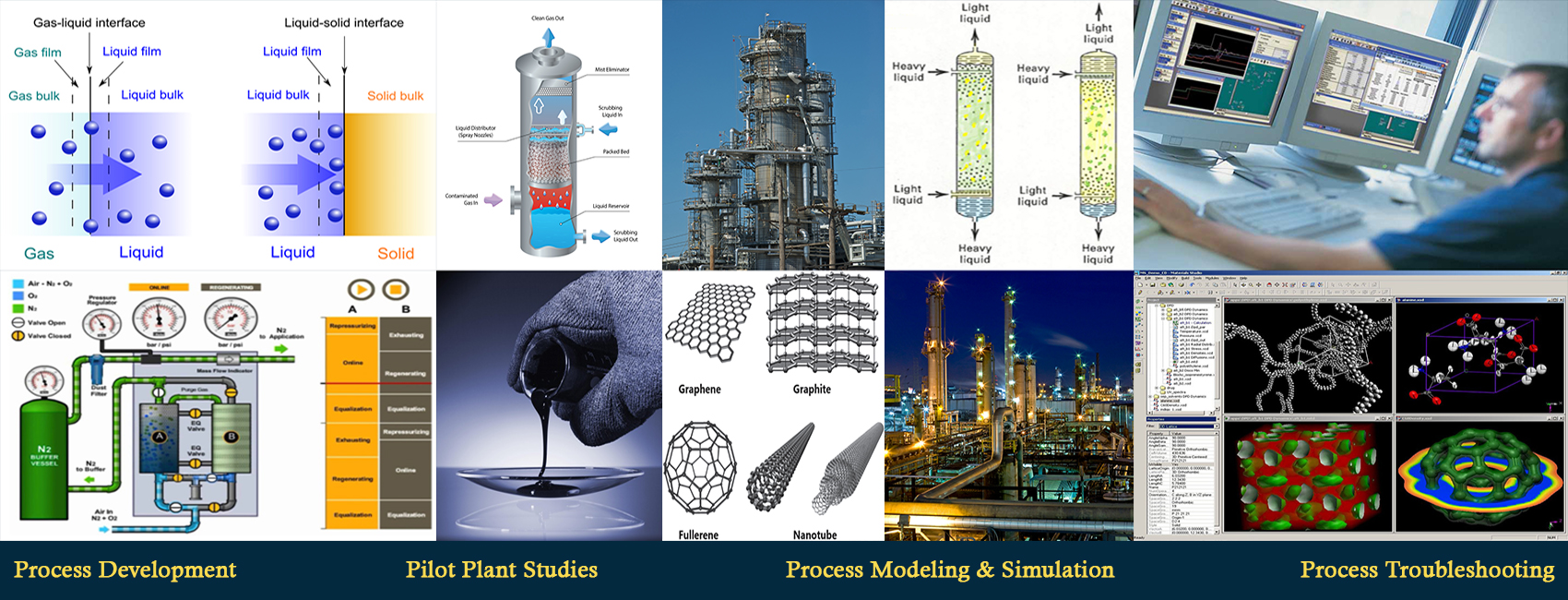

Separation Processes are essential to the chemical, petroleum refining, and materials processing industries, and they account for nearly 40 – 80 % of capital and operating costs in industry. For the chemical, petroleum refining, and materials processing industries as a group, separation technologies are critical for reducing waste, improving energy efficiency, and increasing the efficiency of raw material use. Separation Processes Division (SPD) is involved in research work pertaining to conceptualization and development of energy efficient, economical and eco-friendly processes for separation of impurities or recovery and production of pure components from industrial gaseous streams and refinery/petrochemical hydrocarbon streams (like LPG to Gas oil, Lubes, fuel gases, flue gases etc.)

Several major projects (Govt. of India sponsored, Industry Sponsored and In-house) have been successfully carried out in this division over the years and many developed technologies have been implemented in Indian industries. Additionally the Division also offers Testing and Analytical services like, Surface area and porosity analysis, Skeletal density measurement of adsorbents, Pure component gas and vapor phase equilibrium adsorption isotherm measurement, Dynamic breakthrough measurements and Evaluation of adsorbents under PVSA and PTSA process conditions

Consultancy services pertaining to process conceptualization, Proof of Concept studies, development of Technology Information Package (TIP), process related support for development of Basic Engineering Design Package (BEDP), process optimization, plant adequacy tests, and revamps are also provided by the Division.