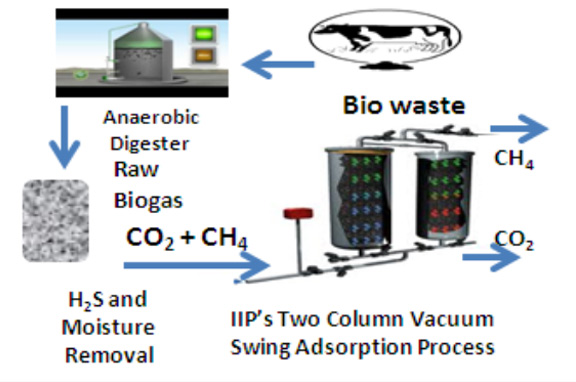

Pressure/ Vacuum Swing Adsorption (PVSA) Process for Biogas Up-gradation to Pipeline Quality Fuel from Raw Biogas

Biogas is one of the renewable energy sources with favorable CO2 balance. It can be formed by biological transformation of large variety of organic wastes. It primarily consists of methane (CH4), carbon dioxide (CO2) and small amounts of H2S and water. The typical composition of bio-gas is Methane (CH4): (55-65%); Carbon Dioxide (CO2): 35-45%; Hydrogen Sulfide (H2S): 0-3%; Moisture (Saturated).

The bio-gas needs to be upgraded to increase its calorific value (Bio-gas: 21.5 MJ/m3 vis a vis Natural gas: 35.8 MJ/m3); to improve flame speed (Bio-gas: 25 cm/s vis a vis LPG: 38 cm/s) and also to remove toxic and corrosive H2S.

The upgraded bio-gas can be used as fuel for gas-engines, boilers, fuel cells, vehicle etc.

Important Parameters unique to the Development

- Process is based on simple VSA cycle configuration.

- The process is designed to operate at low pressure considering availability of biogas at low pressure.

- The process operates with commercially available adsorbent.

- The process can provide methane at a purity of >90% with over 90% recovery

- High purity CO2 can also be produced simultaneously (Purity >90 %).

- The productivity of VSA process (14.05 mol CH4/kg/hr) is 3-4 times higher than similar process reported for biogas up gradation.

Major Application(s)

The process will provide in up-graded biogas which can be used as a fuel in small and medium scale industries, for power generation and as Bio-CNG for vehicular fuel application.

Status of Development

- An existing 10 m3/day feed throughput capacity biogas digester is currently being used as source of raw biogas for in-house testing of the VSA process for validation purpose and to generate scale up data.

- Preparation of a Technology Information Package (TIP) for the Demonstration Plant (500 m3/day capacity) has been completed.

- The proposed unit has been designed and fabrication is underway.

- The process is scheduled to be demonstrated in this pilot plant at an industrial biogas production site in August 2018.

- This demonstration will help CSIR and IIP to showcase and translate this biogas up gradation process for commercialization.