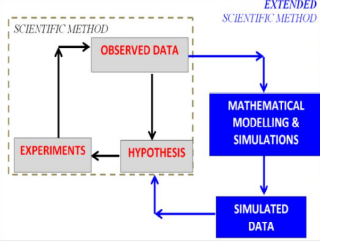

In the continuously evolving chemical process industry and refinery operations due to the planned implementation of process sustainability, incorporating process safety and the much sought profitability aspects requires significant efforts. Modelling and simulation is playing a pivotal role in providing a much needed feedback to the currently used scientific methods for further improvisations. Every process has to undergo successive steps from conceptualization to lab scale experimentation and pilot scale study finally towards industrial scale implementation. Modelling and simulation significantly contributes in the process feasibility studies, process scale up studies, energy and cost estimations, heat integrations within the process emphasising pinch analysis, optimization and revamp/retrofitting of the processes.

We are working in diverse research areas including:

- New process conceptualization

- Scale up and design of lab/bench scale processes via developing and fine tuning simulation model using experimental lab scale data

- Preparation of detailed technology information package for in house developed technologies

- Pinch analysis for energy optimization

- Process integration and optimization

- Revamp studies for process plants

- Synthesizing innovative strategies for plant wide control Molecular modelling and simulation

Major technologies/ processes, involving immense modelling and simulation area contribution, commercialized in industries in few recent years are:

- Simultaneous production of US grade and high purity benzene from unprocessed FCC gasoline in RIL Jamnagar

- Wax deoiling technology for production of food grade paraffin wax at Numaligarh Refinery Assam

- Revamped process for light neutral distillate processing in NMP lube extraction unit at CPCL Mumbai

- Revamped process for changeover of solvent from sulpholane to NMP in food grade hexane at CPCL Chennai

We are having well trained and experienced professionals with commercial softwares available such as ASPEN-HYSYS, COSMOlogic and Material Studio.